Innovative Solutions, Quality, and Performance Since 1936. We do the Impossible.

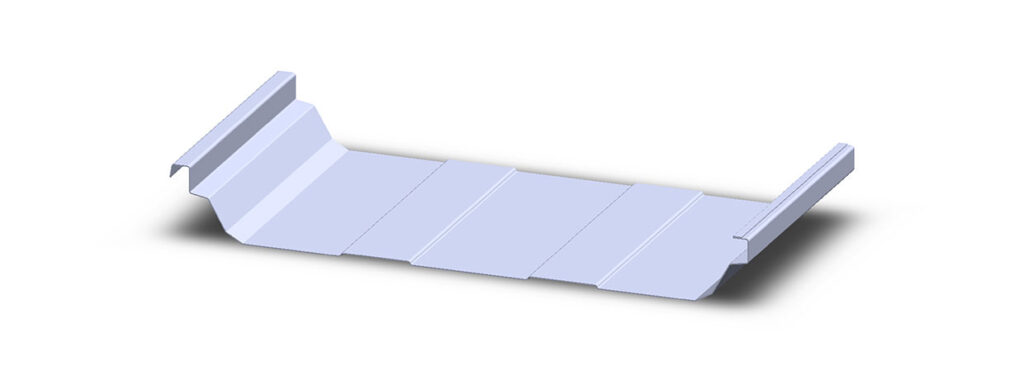

Structural Roofing Machine

This is a large capacity machine for roofs on industrial steel buildings.

Patented Material Handling System:

Independent drive system is always centered on the panel coupled with free spinning forming rollers minimizes oil canning and potential adjustments

Heavy Duty Construction:

2″ welded tubular steel frame, 304 stainless steel forming rollers, steel components powder coated or zinc plated for a tough, long lasting finish.

Proven Technology:

Zimmerman Roll Form Machines are still in use after more than 20 years in the field

Hydraulic System:

Industrial grade hydraulic system with 18 gallon stainless steel tank

Shear:

Guillotine type, blades and dies and manufactured from heat treated tool steel

Lifetime Sealed Bearings:

All bearings permanently sealed and lubricated

Extremely Versatile:

Infinitely adjustable from 16″ to 24″

Quick Width Change Over:

Panel width can be changed easily and quickly

Length:

144″

Height:

28″

Width:

48″

Weight:

3,850 lbs.

Speed:

60 feet/minute

Power:

13 HP Electric Start Gasoline Engine

Shear:

Hydraulic, Guillotine

Coil Width:

22″ to 30″

Materials:

Steel to 20 ga.

Aluminum to .040″

Copper to 32 oz.

- One Set of Tooling to Form One Profile

- 304 Stainless Steel Tooling

- Stiffening Rib or Striation Assembly

- 13 HP Electric Start Gas Engine OR 220 VAC Single Phase Electric Motor

- Limit Switch Measuring Device

- Hand-held Remote Controls

- Industrial Grade Hydraulic System

- 4,000 lb Capacity Expandable Decoiler with Brake & Stand

- Electric Seamer

- Hand Seamer

- Vinyl Cover

- De-coiler Over the Top Mounting System

- 50’ Variable Height Run Out Stands

- Dual Power (Gasoline and electric)

- Digital Batch Controller

- Stiffening Rib or Striation Assembly

- Pivot Mount Base