Innovative Solutions, Quality, and Performance Since 1936. We do the Impossible.

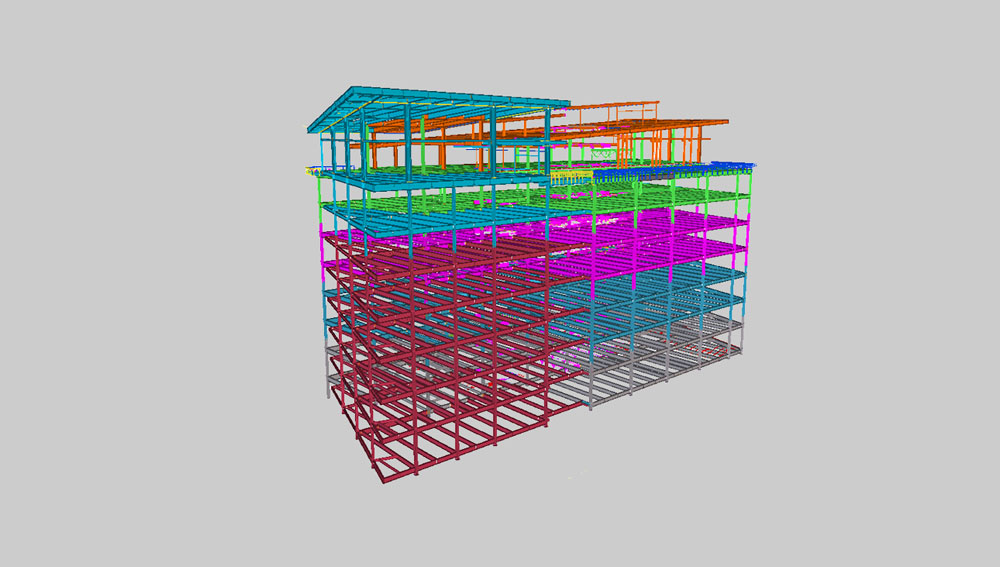

Our project managers give you peace of mind that steel will be on the job site to your schedule. We are accountable for providing oversight of the shop drawing process based on contract documents and specifications. We have strong ties to steel mills and an efficient production management operating system.

CU CASE

For CU CASE, we executed a unique manufacturing capability that required boring a 2″ diameter cavity, 9″ deep at a compound angle to the girder, with our 250″ table vertical bridge mill.

Denver Botanic Gardens’ Tree Columns

The atrium portion of the project featured four “Tree” columns that utilized 60 total rolled and mitered beam members to create the intricate assemblies. Vast and precise cutting & fitting of the members led to a clean but intensive erection process given the very tight tolerances required by the project details. The impressive finishes were achieved in our self performed AISC SPE-P1 Sophisticated Paint facility.

Learn More About How We Manage a Project’s Lifecycle…

Design Assist

Pre-Construction Optimization

Production Execution

Erector Partnerships

- AISC – BU, Certified Building Fabricator

- AISC – IBR, Certified Bridge Fabricator, Intermediate

- AISC – CBR, Major Steel Bridges

- AISC – FCE, Fracture Critical Endorsement

- AISC – CCE-1,2,3 Complex Coatings Endorsement

- 150,000 sq. ft. Facility

- 20,000 sq. ft. Enclosed Surface Prep & Paint Area

- 15,000 tons annual capacity

- Combined 50 ton Crane Lifting Capacity

- Automated Beam Processing

- Drilling, Shearing, Coping & Cambering

- Forming

- Plasma & Laser Cutting

- Saw Cutting

- Machining

Multi-Level Buildings | Offices | Hospitals | Schools | Resorts | Bridges & Highways | Handrails & Stairs | Misc. Metals

We are hiring...are you looking for an exciting career in the industry? Zimmerman offers technical, skilled trades and back-office careers in a reputable team with over 7 decades of manufacturing excellence legacy in high technology applications.