Innovative Solutions, Quality, and Performance Since 1936. We do the Impossible.

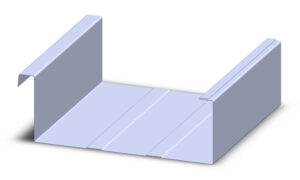

Arch Roofing Machine

This quick span system is renowned as the fastest building system in the world. Used in applications such as aviation and military hangars, and agricultural food storages.

Panel Forming Machine

12 forming stations, independent drive system, 304 stainless steel forming rollers, powder coated paint finishes, heavy duty welded tubular steel frame, lifetime sealed bearings.

Panel Curving Machine

4140 heat treated and hard chrome plated pumpkin and side crimp rollers, 304 stainless steel guide rollers, powder coated paint finishes, heavy duty welded tubular steel frame.

Trailer

Heavy duty tandem axle with electric brakes, 18,000 lb. (8,163 kg) capacity, tool and spare tire storage in rear of trailer, one spare tire & wheel, collapsible tongue for shipping in 20 ft. sea container.

Gasoline Engine

24 horsepower, electric start.

Hydraulic Drive & Control System

Run-out Table System

Adjustable extension legs, 100 ft. (30.5 M) straight panel tables, 100 ft. (30.5 M) curved panel tables, trailer mounted storage rack for transporting tables.

Lifting Equipment

one 18 ft. 6 in. (5.6 M) long spreader bar lifting device complete with lifting eye, cables, threaded pin clevises, and special brackets for attachment to curved panels.

Coil Rack with Expandable Arbor

5,000 lb. (2,267 kg.) capacity with friction type brake.

Seaming Machines

2 each, 120 volt AC (240 volt AC available on request) seaming machines for

attaching both straight and curved panels, and 1 each hand seamer.

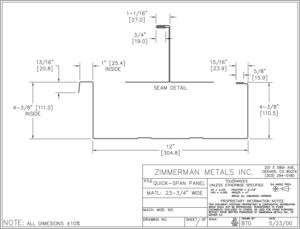

Coil

23 3/4″ (603mm) wide x .029″ (0.7mm) through .040″ (1.0mm) thick

Trailer

23 ft. 5 in. (7.15 M) long x 7 ft. 6 in. (2.29 M) wide x 7 ft. 9 in. (2.36 M) high

Weight

14,500 lbs. (6,576 kg) with all of the above equipment.